Focusing on Casting, Forging & Machining for almost 20 years, J.B has developed into a leading integrated enterprise providing engineering and fabrication solution of customized components. We have two production bases, the headquarter in China and a plant in Cambodia. With casting & forging capacity over 6000 tons per year, more than 200 workers and over 20,000 sqm land area, your un-scheduled quantity and delivery time demands can be fully guaranteed.

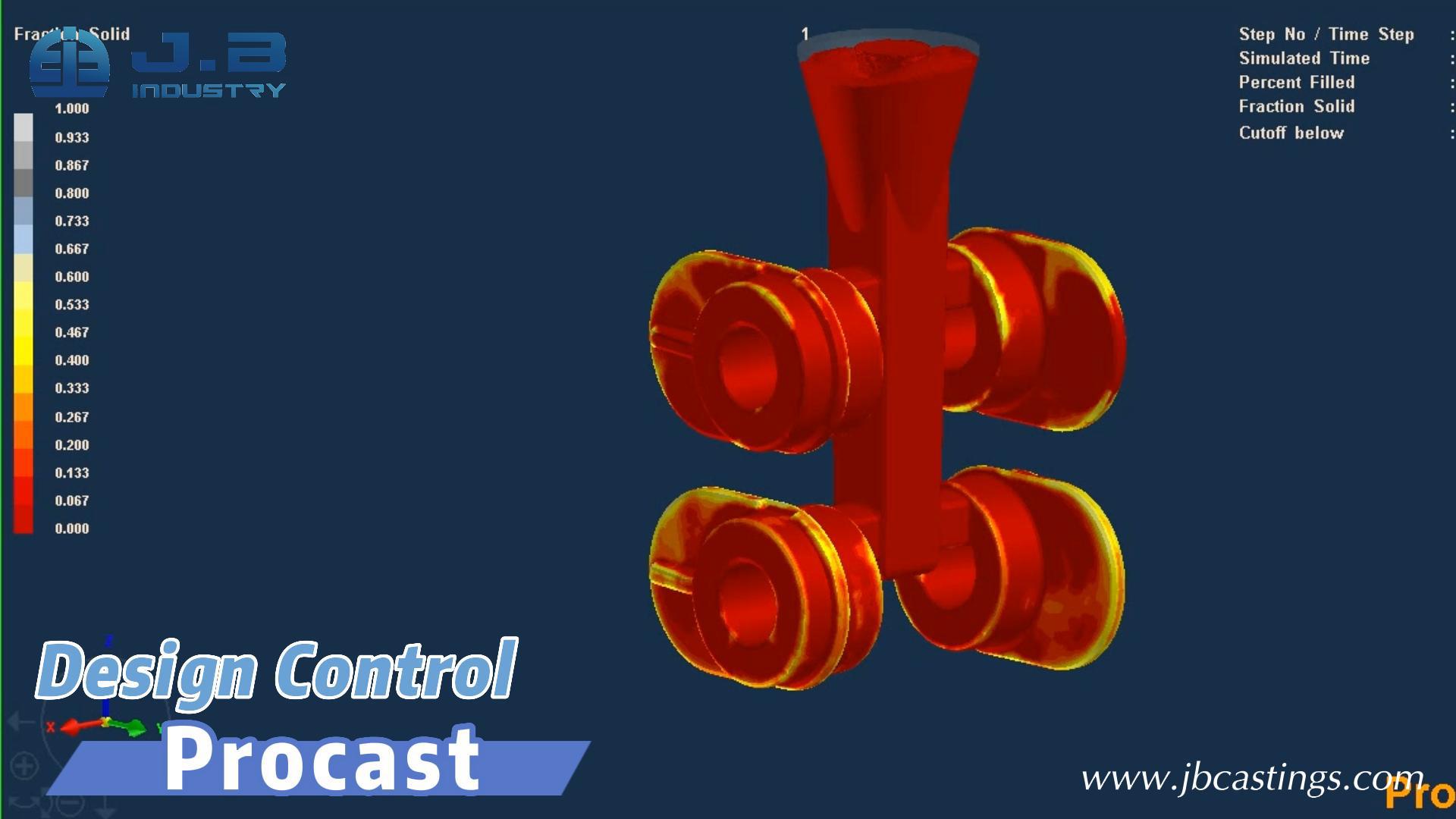

We are capable of re-designing parts for you, which are originally made from other manufacturing process, like weld-assembly or flame cutting, utilizing our rich engineering experiences integrated with powerful designing tools, like CAD, UG, Pro-E, Solidworks and Pro-Cast software used for casting solidification simulating. Certified by IATF16949, ISO9001, ISO14001, ISO45001, ISO3834 EN15085 and a number of invention patents, J.B won the "High-tech Enterprise" and "National Gazelle Enterprise" titles. In J.B, you'll find that prototype lead time can be greatly shortened, while accuracy of dimensions and of shape extremely got improved.

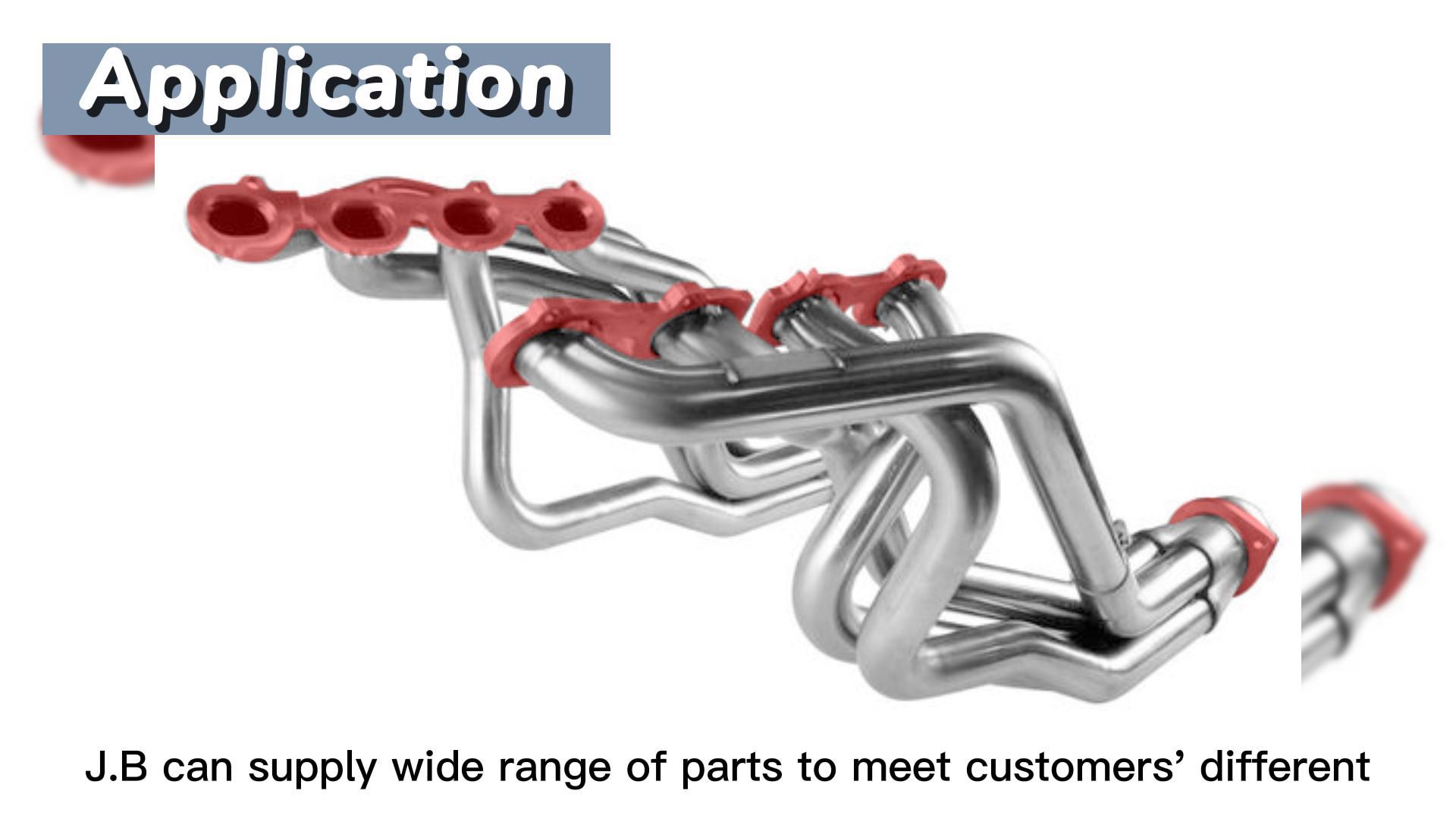

We also offer a wide range of material selections, covering steel, stainless steel, aluminum, cast iron and ductile iron. "Value Added" process is also available to fully meet your requirements, including Heat-treatment, Non-destructive Test, Machining, Welding, Plating, Painting and Assembly etc. Parts are widely used in Construction, Agriculture, Automotive, Mining, Transportation, Manufacturing and other industries.

J.B. is dedicated to be your trustworthy and reliable partner of customized products, working together to achieve industry leadership and sustainable growth!